Compensation Procedure After Failed SPAT Tests Using the USB FaroArm

Overview

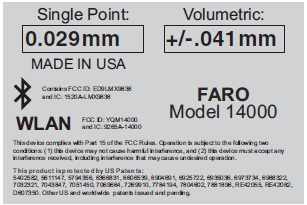

The FaroArm is a precision tool. Consequently, changing conditions in your work environment may cause the accuracy of your FaroArm to fall out of tolerance as stated in the in the Single Point Value field on the accuracy specification label attached to your FaroArm.

If you have performed a SPAT test in the Measure software several times with consist results, and the test results are consistently higher than the Single Point value printed on the accuracy label attached to your FaroArm, you can bring the FaroArm back into tolerance by compensating it within your new work environment.

NOTE: Make sure you validate that the FaroArm is out of tolerance by performing multiple SPAT tests before you run the compensation. Compensation changes the factory compensation settings. Do not run the FaroArm compensation if the SPAT tests are within tolerance.

Detailed Steps

- Check the stability of the FaroArm mounting before you begin. Compensation takes the FaroArm through its full range of motion. If the mount is not stable, the compensation will not be accurate.

- Position the FARO compensation cone within 2/3rds of the FaroArm's reach, as measured from the FaroArm base.

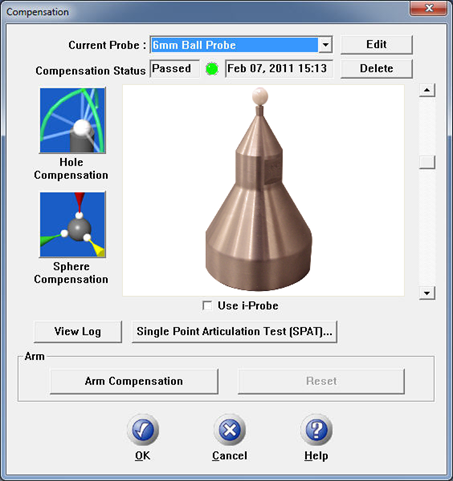

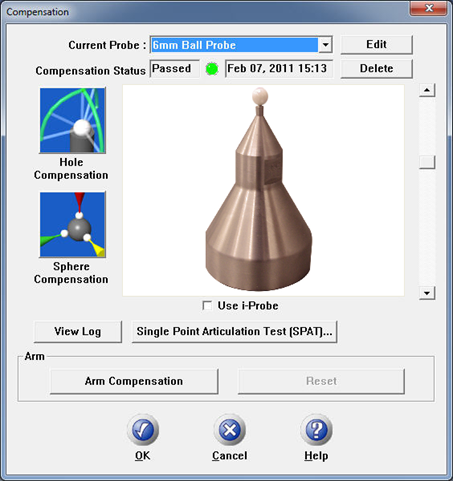

- Attach the FaroArm to your computer, go to Measure, and click Devices > Hardware Configuration > Probe Compensation to access the Compensation dialog box. Click Arm Compensation.

- Place a properly compensated probe firmly in the compensation cone.

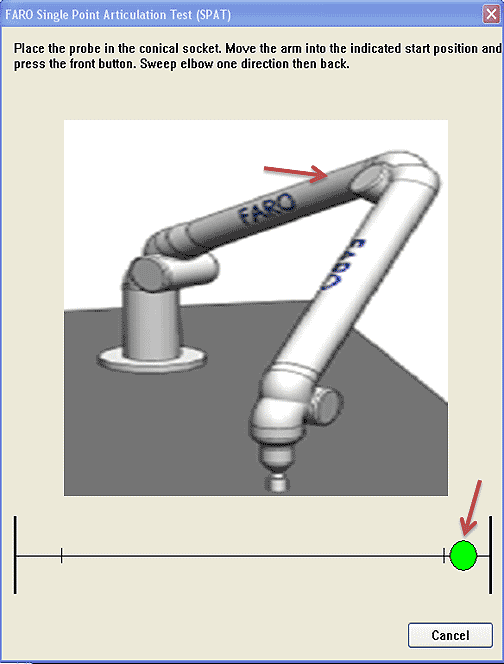

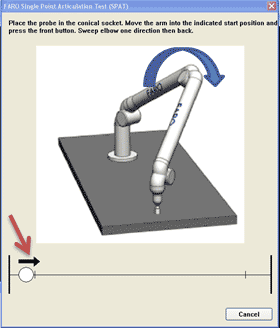

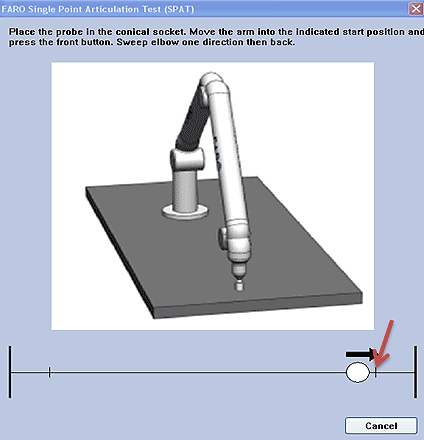

NOTE: Compensate the probe before you run the FaroArm compensation. - Hold the FaroArm as shown in the image below and move the elbow until the ball indicator is at either end location and has turned green. On the FaroArm, click the top green button once.

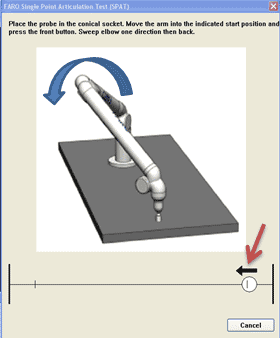

- Slowly flip the FaroArm to the direction indicated by the black arrow in the dialog box. Do not press the green button on the FaroArm. The software will take a total of 20 points automatically.

- Once the black arrow in the dialog box changes direction, flip the FaroArm in the opposite direction.

- Continue to move the FaroArm until the ball indicator crosses over the position indicated by the red arrow in the image below.

Prompts appear to indicate if the X,Y, and Z coordinate data sets were or were not repeatable. - To check that the compensation was successful, repeat the SPAT tests and compare the new results with those you were getting before you ran the compensation.

NOTE: If you need to return your FaroArm to the factory compensation settings, in the Compensation dialog box click Reset.

Next Steps

Your device is ready to use.

See Also

Keywords:

SPAT, accuracy, tolerance