Measuring Threaded Holes

Overview

This article gives a brief description of how to use a FaroArm® to properly measure the position of a threaded hole.

Setup

The FaroArm should be mounted on a tripod or fixed in a manner that prevents any movement throughout the measurement process.

Be sure that part does not move significantly while in the process of taking measurements.

Process

- The FaroArm can be used to measure threaded holes/bores to define positioning of the hole only. If you are attempting to measure the major and minor diameters of a threaded hole, you will need to use a thread gage. If at all possible, it is recommended that you measure holes prior to tapping threads.

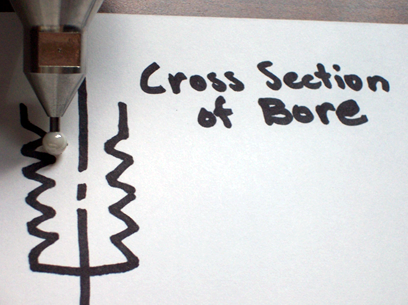

- Because the diameter of the hole does not affect the center point of the corresponding circle or cylinder, we can measure the circle/cylinder on the threads.

- Assuming the threads are cut at the same height around the entire hole, we can reference points on the threads at various locations around the hole.

- Make sure that the probe is seated between two threads. Basically, the threads are used to constrain the ball from sliding up and down the walls of the hole.

- The hole can be measured as a circle or a cylinder, the important aspect is to be sure that the ball is seated between threads each time a point is taken.

Note: you may have to experiment with different ball probes to find one that seats in your particular threads consistently.