Workholding Kit (900-000034-000) for the 8-Axis

Overview

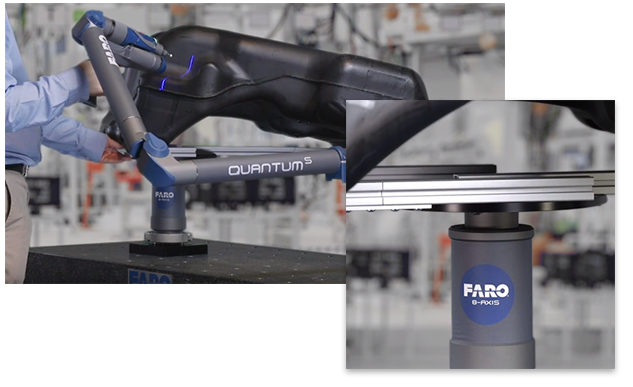

The FARO® 8-Axis Workholding Kit (for use in conjunction with the 8-Axis), provides many solutions to workholding challenges for large or odd shaped parts. Solid and repeatable workholding is a must for accurate measurements, scans, and scan registration. P/N: 900-000034-000, contact your regional FARO account representative for ordering information.

Warning: The FARO 8-Axis maximum weight capacity is 220lbs (100kg). The user assumes all responsibility and risk for ensuring parts mounted to the 8-axis are secure, load balanced, and does not present a tipping hazard. FARO Technologies, Inc. disclaims any liability for injury, death or damages resulting from the use thereof.

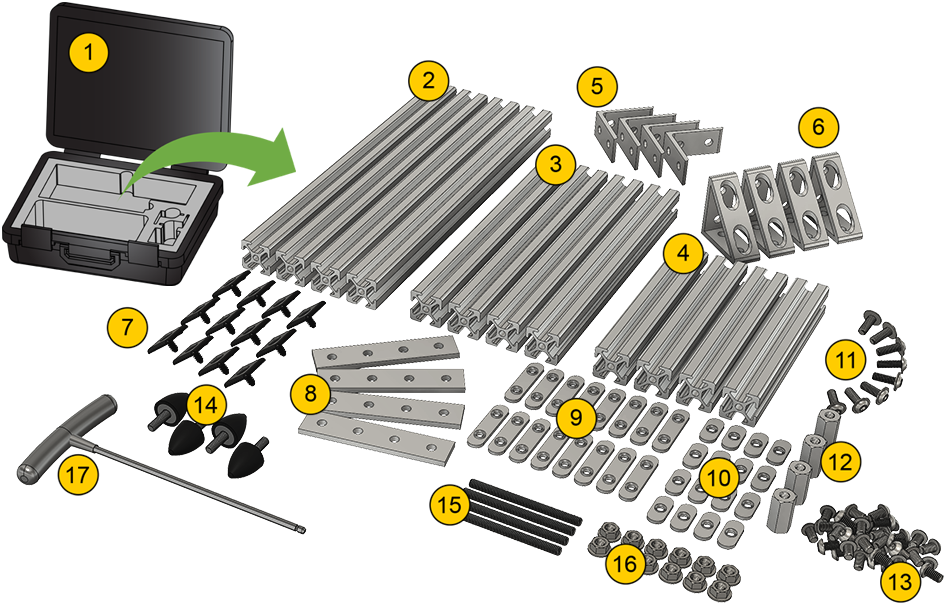

Kit Contents

| Item# | Qty | Description | Item# | Qty | Description | |

|---|---|---|---|---|---|---|

|

1 | Case |  |

16 | M6 Centered Slide-in T-Nut | |

|

4 | Rail, T-Slot, 25 x 25 x 300mm |  |

8 | M6 x 16 Flanged Button Head Socket Cap Screw | |

|

4 | Rail, T-Slot, 25 x 25 x 225mm |  |

4 | M6 x 25mm, Female/Female Standoff | |

|

4 | Rail, T-Slot, 25 x 25 x 150mm |  |

50 | M6 x 10 Button Head Socket Cap Screw | |

|

4 | Tall Inside Corner Bracket |  |

4 | Load-Rated Bumper (22lbs), M6 x 18mm Threaded Stud | |

|

4 | Gusseted Inside Corner Bracket |  |

4 | M6 x 80mm Threaded Rod | |

|

12 | End Cap with Push-in Fastener |  |

12 | M6 Flanged Nut | |

|

4 | 4 Hole - Straight Flat Plate |  |

1 | Hex Key, T-Handle, 4mm | |

|

16 | M6 Double Slide-in T-Nut |

Application Examples

|

|

|

Basic Usage and Tips

While its not possible to cover every workholding configuration, below are some basic guidelines to keep in mind.

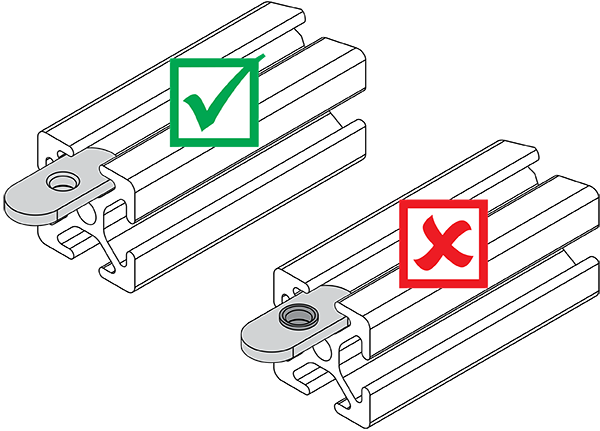

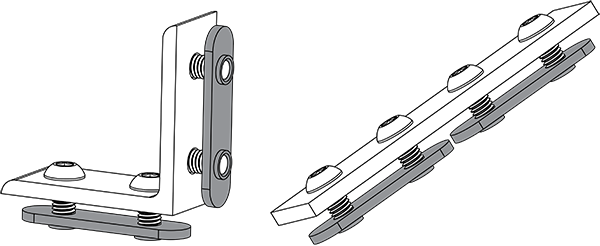

T-Nuts

- When using T-Nuts, be sure the small protrusion of the thread faces down into the channel of the rail.

- Use of the Double T-Nuts can simplify assembly and save time when using flat plates and corner brackets.

- Whenever possible "preload" T-nuts with the fastener(s). Slide the assembly into the end of the rail, position and then tighten. This will eliminate the task of aligning the fastener to threaded hole afterwards.

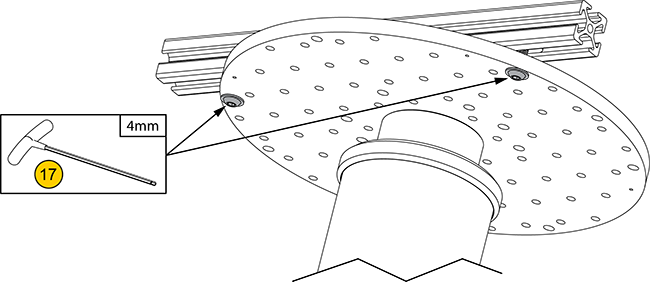

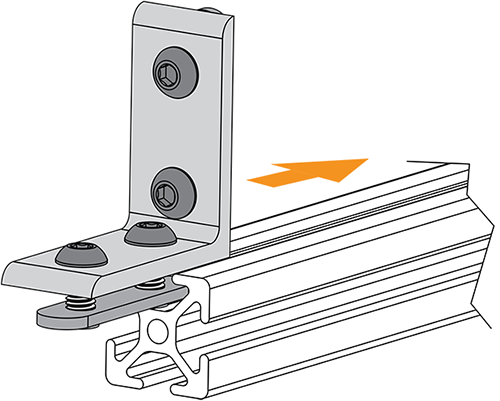

Attaching Rails to the 8-Axis Plate

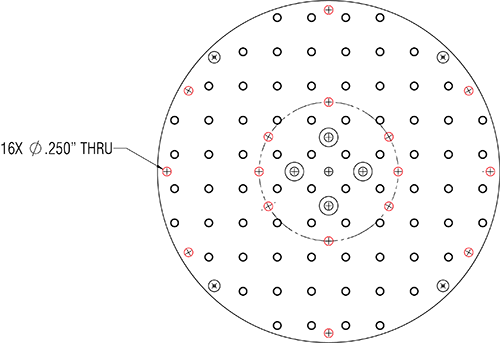

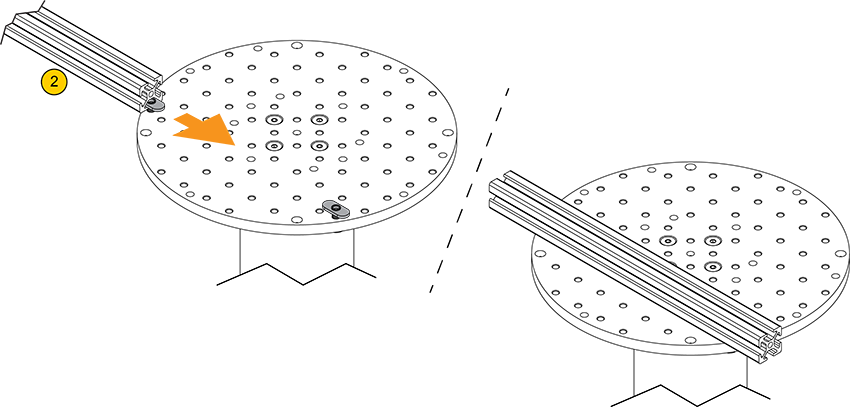

When attaching rails directly to the 8-Axis Plate, it is important observe the mounting locations that will allow the fasteners to pass through the hole and thread into the corresponding T-Nut.

- Most of the holes on the 8-Axis plate are threaded, the locations of non-threaded through holes are shown in red below. To eliminate unwanted movement it is recommended to have at least two mounting points per rail section.

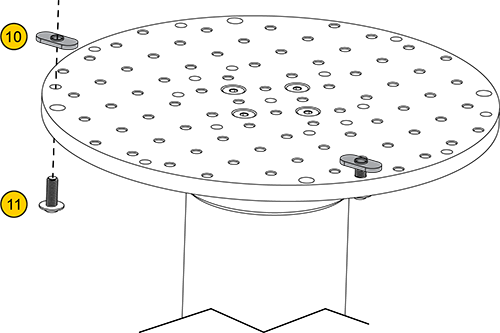

- Using two M6x16 Flanged Screws

and a M6 Centered Slide-in T-Nuts

and a M6 Centered Slide-in T-Nuts  , assemble them through the plate as shown (using non-threaded holes). Leave the fasteners loose to allow the rail to slide over them in the next step.

, assemble them through the plate as shown (using non-threaded holes). Leave the fasteners loose to allow the rail to slide over them in the next step.

- Slide the desired Rail over the two T-Nuts. (The 300mm rail

is long enough to span the diameter of the plate.)

is long enough to span the diameter of the plate.)

- Position the rail as desired and tighten the two screws.