Calibration Certificates for the FaroArm

Overview

Every FaroArm® is delivered with a calibration certificate as courtesy to show that the individual ball diameters were inspected and certified to eliminate the need for probe diameter qualification. This article will breakdown a certificate and provide an understanding of how to read it and what it means to you.

After device delivery, regularly scheduled probe certification should be completed by a qualified local service provider or a company's internal certification service to satisfy quality requirements.

Certificate Examples

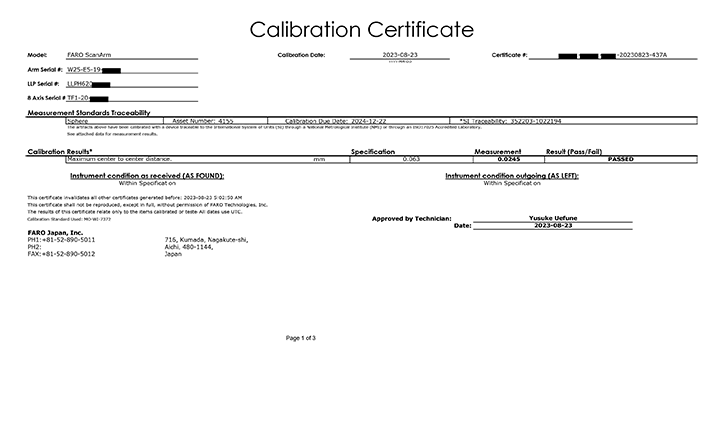

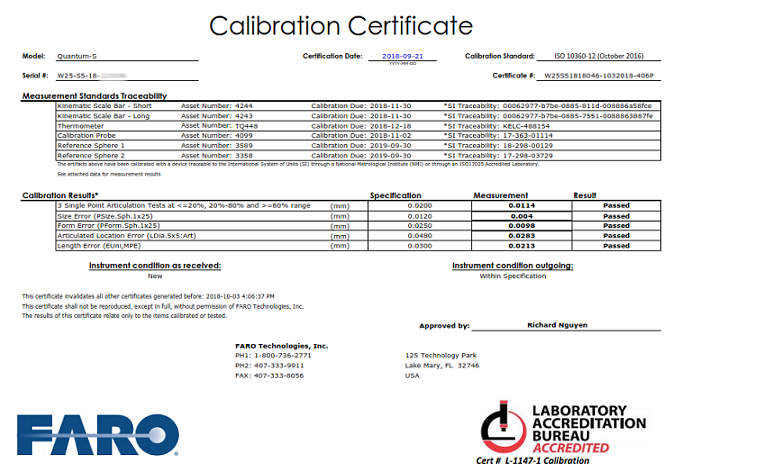

Quantum Series FaroArm

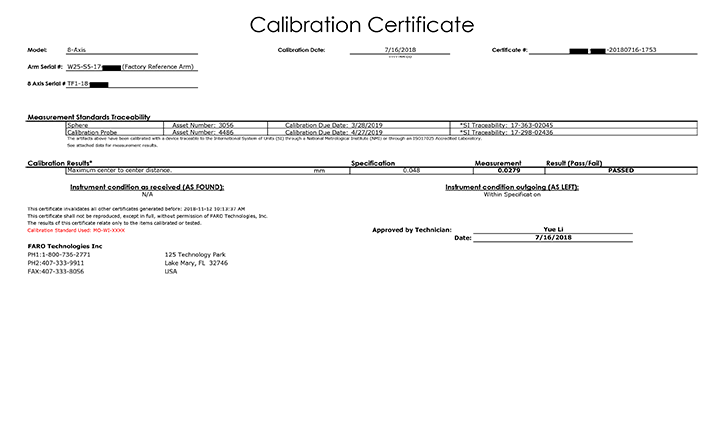

Edge FaroArm

Certificate Anatomy

- Model: FaroArm model.

- Serial #: FaroArm's unique identification number.

- Certification Date: When certification was issued.

- Calibration Standard: Standard used to calibrate the FaroArm.

- Certificate #: Certification number issued to the FaroArm.

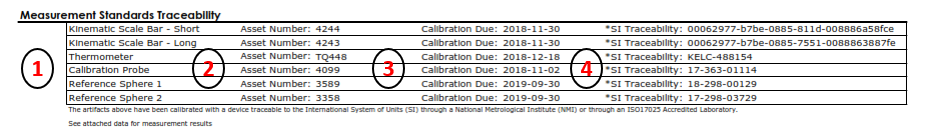

Measurement Standards Traceability Chart

Primarily used as an auditing reference and your source of confidence in that your FaroArm will meet quality standards.

-

Artifact used: Certified internal artifact used in the calibration process.

- Asset number: Number used to serialize artifacts for internal reference and traceability.

- Calibration due date: Due date for each certified artifact. Ensures at the date of certification, artifacts used in calibration were within compliance.

Note: This date does not represent your FaroArm's due date for calibration recertification. It applies only to the artifact's calibration, not your device.

- SI Traceability number: Referencing number to show that FARO® has used calibrated artifacts with traceability to the International System of Units.

Calibration Results Chart

A summary of the individual tests performed and the results. The (1) column are tests performed on your FaroArm during calibration.

- Test Performed: Calibration test performed, per 10360-12 standard. Use the "ISO 10360-12 Standard" section below to get an idea of what each test entails.

- 3 Single Point Articulation Tests (SPAT)

- Psize

- PForm

- LDia

- EUni

- Specification: Our standard for the model.

- Measurement: Result (Will be the largest error during testing)

- Result: Passed or Failed.

Instrument condition as received and outgoing

- New: Factory-grade new.

- Within spec: Passed all testing.

- Not within spec: Did not meet FARO standard during testing, specific to your device.

- Inoperable: Testing was not able to be completed. Device may not be fully functioning.

ISO 10360-12 Standard

This standard requires four probing and one distance test. The test's results are an error and each test has a Maximum Permissible Error (MPE).

Sample Report

Click here to see a sample report individual calibration results and their meanings. Note: This sample report is for an older FaroArm model based on the ASME B89.4.22 standard.

In the report, measurements are conducted in terms of length, Arm positions and quadrants.

Quadrant locations on each FaroArm model: