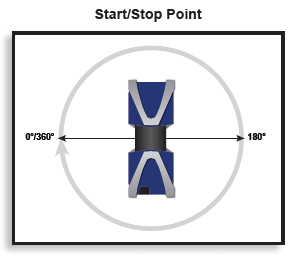

Mis-Alignment Occurs at the Seam of 0 and 180 Degrees as the Focus3D Rotates

On the FARO Laser Scanner, the laser is reflected off the mirror from both the front and back. So, the scanner only rotates 180° along the horizontal axis to capture a 360° scan, as shown in this image. When in Planar View, you may see what looks like a mis-alignment at the point where the scanner starts and stops its rotation. This point is also referred to as the seam.

Here is what you can do to check if a mis-alignment really exists around the seam area.

- Make a selection around the seam area.

- Right-click on the selection and select View > 3D View.

- In the 3D View, rotate around the seam area looking for any mis-alignment.

If the scanner is performing within factory specifications and you see a mis-alignment, it should not exceed the factory-stated tolerances for your scanner. You can click the links in the See Also section of this article to view the technical specifications for different Focus3D Laser scanner models.

See Also

- Missing Scan Points Near the Bottom of the Scan Area for the Focus3D Laser Scanner

- Technical Specification Sheet for the Focus Laser Scanner

- Technical Specification Sheet for the Photon Laser Scanner

Keywords:

spec, techsheet, tech sheet, accuracy, seam error, degrees, seam gap, collimation error