Characterizing Tooling Points Using BuildIT Bundling Registration

OverviewBuildIT’s “Bundling Registration” command allows registering a network of devices which are measuring common points. This registration allows creating “bundling points” that combine measurements of the same targets, taken from multiple viewpoints. |

Highlight Video: |

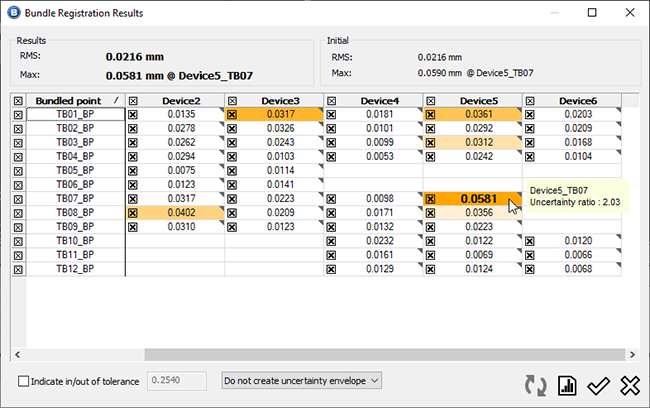

The uncertainty ratio of each point is displayed, and outliers are flagged. The command allows multiple scenario simulations to be run before accepting an alignment.

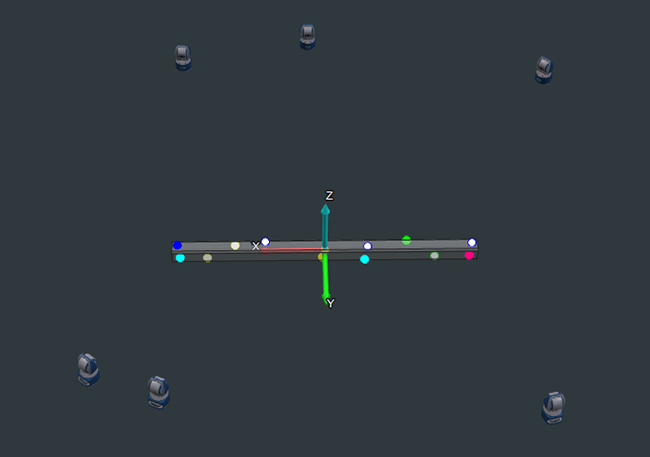

The uncertainty envelope of measurements and resulting bundling points can be visualized in 3D view.

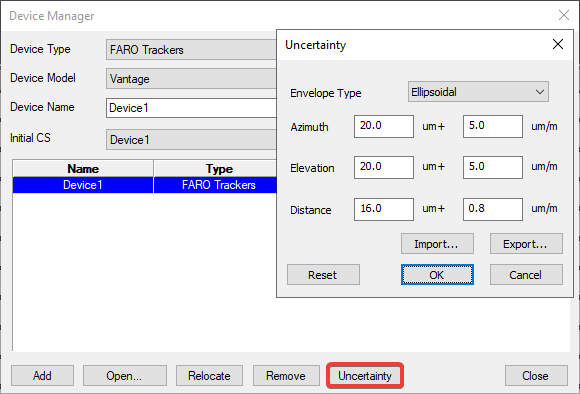

Default values are taken from the device’s datasheet. However, the uncertainty of each device can be fine-tuned based on calibration report values via the Device Manager:

Benefit

Combining measurements taken from multiple viewpoints allow reducing the uncertainty on the location of the resulting points. Flagging and ignoring outliers grants user full control over the quality of the output.

Typical Use Case

Typical Use Case

The Bundling Registration command is typically used for characterizing the actual location of tooling points on a jig or on a fixture. Those are used for future alignments when performing the assembly or verification of that jig or fixture using a laser tracker.

Finely characterized points allow obtaining a consistent alignment to the part regardless of which targets are being measured on subsequent inspections.

Another benefit of having a finely characterized set of points is that it allows computing the scale at the moment of computing the alignment, eliminating the need for recording the actual temperature of the part and applying this scaling manually based on the part material - thus reducing the risks of error.

Workflow

- When characterizing tooling or equipment, allow the part to soak in the environment so that it attains a stable temperature.

- Repeat the following steps from multiple device locations:

- Add a new device (“Device: New” or “Device: Relocate”).

- Set the device’s scaling based on the jig’s material and temperature (“Align: Set Scaling”)

- Measure the tooling points which are visible from this position (“Inspect: Point”)

- Once the tool has been measured from enough positions, run the bundling registration command (“Align: Bundling Registration”). This creates Actual points labeled with the “_BP” suffix

- Convert those Bundling Points to Nominal (“Edit: Change Type”). These should be saved in the model as the actual position of the tooling points

- Those points' coordinates are often stamped on the jig or fixture to serve as a reference in the future

Best-practices

Keep in mind that for a laser tracker:

- Uncertainty envelope is thinner along the radial direction. Positions should be as spread out as possible around the part

- Uncertainty envelope grow linearly with the distance from the tracker. Points should be measured from as near as possible

- Points with a high uncertainty ratio generally indicate that at least one measurement was not performed properly (dirt in nest, probe not properly seated, etc.). We recommend removing the worse point and recomputing the alignment. Repeat as necessary.