Common Laser Tracker Workflows

Overview

FARO® Laser Trackers are accurate, portable coordinate measuring machines that enable you to build products, optimize processes, and deliver solutions. This article contains common workflow solutions to help streamline productivity.

- Aligning the Laser Tracker to Robot Systems

- Aligning Tracker to Automotive Check Fixture

- Alignment and Measurement to Tire Machine

- Alignment Inspection of a Tire Machine

- Gravity as a the Clocking Axis of a Coordinate System – Measure Q/X

- Gravity as a the Clocking Axis of a Coordinate System – Measure 10

- Gravity as Primary Vector of a Coordinate System

- How to Level an AIDA Stamping Press

- Inspecting Sheet Metal Check Fixture

- Inspection – Best-Fit Alignment to a Tube

- Laser Tracker and changes to Robot Systems

- Level a Part to Gravity

- Peterbilt Rail Inspection

- Reverse Engineering Complex Surfaces

- Survey feature with Tracker – Measure 10

- Survey feature with Tracker – Measure

- Vacuum Base Setup

Aligning the Laser Tracker to Robot Systems

This document details the process of aligning the track of Robot to a Break Press.

Aligning Tracker to Automotive Check Fixture

This file outlines the steps for establishing a best fit (iterative) alignment to a fixture with three or more known locations.

Alignment and Measurement to Tire Machine

This document explains how to align a tire machine's rails and transfer ring.

Alignment Inspection of a Tire Machine

This method sheet describes one method to align, inspect, and setup a tire machine.

Gravity as a the Clocking Axis of a Coordinate System – Measure Q/X

This file explains how to setup a coordinate system in Measure in situations where it is desirable to use a gravity vector (like a plumb bob) to “clock” the coordinate system.

Gravity as a the Clocking Axis of a Coordinate System – Measure 10

This file explains how to setup a coordinate system in Measure 10 in situations where it is desirable to use a gravity vector (like a plumb bob) to “clock” the coordinate system.

Gravity as Primary Vector of a Coordinate System

This document demonstrates how to create a coordinate system in situations where it is suitable to use gravity as the vector of the primary plane of a coordinate system. This type of coordinate reference frame is useful when leveling machine beds, rails, and assembly lines and useful when inspecting a part for sag due to gravity or normal wear.

Back to topHow to Level an AIDA Stamping Press

This document describes the method for leveling a stamping press.

Inspecting Sheet Metal Check Fixture

This file details the method for aligning the Laser Tracker to sheet metal fixtures with known points with the intent of comparing the fixtures to a CAD model.

Inspection - Best-Fit Alignment to a Tube

This document explains how to complete a best-fit alignment of the non-end intersection points of a tube in order to produce a more repeatable alignment for measuring a tube without a square-cut end.

Laser Tracker and changes to Robot Systems

This file demonstrates the process of capturing the locations of several items in the world of a Break Press robot.

Leveling a Part to Gravity

This file demonstrates how to adjust a part, or the base of a part or fixture so that it is level to gravity.

Back to topPeterbilt Chasis Rail Hole Locations Inspection

This guide explains a procedure aiding in the inspection of hole locations on a Peterbilt chasis.

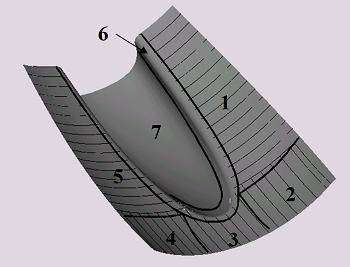

Reverse Engineering Complex Surfaces

This presentation describe the main workflow for reverse engineering a part with complex surfaces.

Survey feature with Tracker – Measure 10

This document explains how to use the survey functions in Measure 10.

Survey feature with Tracker – Measure

This document explains how to use the survey functions in Measure.